The Free Weekly Forklift Inspection Checklist Template You Need: Stay Safe and Compliant

Forklifts are essential tools in warehouses, construction sites, and various industries. Their power and efficiency, however, come with inherent safety risks. Regular inspections are not just a good practice; they’re often a legal requirement to ensure the safe operation of these machines and the well-being of your workforce. That’s why having a reliable and easily accessible forklift inspection checklist is paramount. This article provides you with a comprehensive understanding of forklift inspections, why they’re crucial, and, most importantly, offers you a free, downloadable weekly forklift inspection checklist template to streamline your safety procedures.

Why Weekly Forklift Inspections Are Non-Negotiable

Operating a forklift involves a multitude of moving parts and potential hazards. Regular inspections are your first line of defense against accidents, injuries, and costly downtime. Weekly inspections, in particular, offer a balanced approach, providing a frequency that allows for early detection of wear and tear without being overly burdensome. Here’s why weekly inspections are vital:

- Compliance with Regulations: OSHA (Occupational Safety and Health Administration) and other regulatory bodies mandate regular forklift inspections. Failing to comply can lead to hefty fines and legal repercussions.

- Preventative Maintenance: Inspections identify potential issues before they escalate into major breakdowns, minimizing repair costs and extending the lifespan of your equipment.

- Enhanced Safety: Detecting and addressing safety hazards, such as damaged forks or malfunctioning brakes, significantly reduces the risk of accidents and protects your employees.

- Reduced Downtime: Catching problems early prevents unexpected equipment failures, keeping your operations running smoothly and efficiently.

- Improved Productivity: Well-maintained forklifts operate more reliably, leading to increased productivity and reduced operational inefficiencies.

Key Components of a Comprehensive Forklift Inspection Checklist

A thorough forklift inspection checklist should cover all critical areas of the machine. Here’s a breakdown of the key components you should include:

- Pre-Operational Checks: These are performed before each shift and include:

- Visual Inspection: Checking for leaks (oil, fuel, hydraulic fluid), damage to forks, mast, overhead guard, and tires.

- Fluid Levels: Verifying the oil, coolant, and hydraulic fluid levels.

- Tire Condition: Inspecting for proper inflation, tread wear, and damage.

- Horn, Lights, and Signals: Ensuring all lights (headlights, taillights, warning lights), horn, and backup alarms are functioning correctly.

- Seatbelt and Operator Controls: Checking for proper operation of the seatbelt, steering, brakes, and other controls.

- Weekly Inspection Focus: Building upon the pre-operational checks, the weekly inspection requires a deeper dive:

- Battery Inspection (Electric Forklifts): Checking the battery terminals, electrolyte levels, and overall condition.

- Fuel System Inspection (Internal Combustion Forklifts): Examining the fuel lines, connections, and fuel tank for leaks.

- Steering System Inspection: Checking for play in the steering wheel and ensuring smooth operation.

- Brake System Inspection: Testing the service brakes and parking brake for proper function.

- Mast and Fork Inspection: Looking for cracks, bends, or damage to the mast and forks.

- Safety Devices: Verifying the functionality of the backup alarm, horn, and other safety features.

- Record Keeping: Documenting all inspections, findings, and any corrective actions taken.

Get Your Free Weekly Forklift Inspection Checklist Template

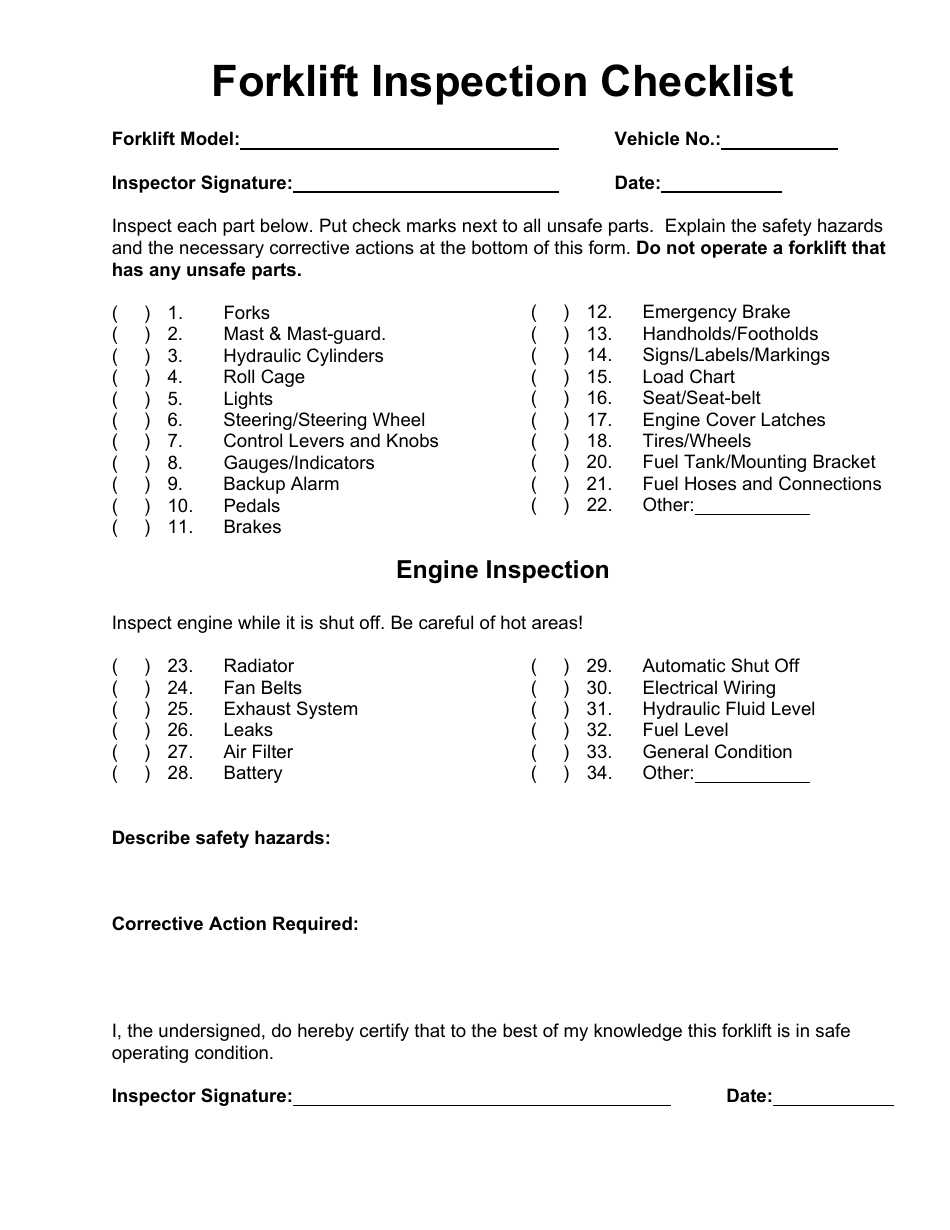

To simplify the inspection process and ensure you cover all the necessary areas, we’re providing you with a free, downloadable weekly forklift inspection checklist template. This template is designed to be easy to use, comprehensive, and customizable to fit your specific forklift models and operational needs.

[Insert Link to Downloadable Template Here] (Example: “Download the free template here: [link to your website/hosting service]”)

This template includes:

- A detailed checklist covering all essential inspection points.

- Space for recording the forklift’s identification number.

- Sections for noting any deficiencies found.

- Space for documenting corrective actions taken.

- Signature lines for the inspector and supervisor.

Implementing and Maintaining Your Forklift Inspection Program

Simply having a checklist isn’t enough. Here’s how to effectively implement and maintain your forklift inspection program:

- Training: Ensure all operators are properly trained on forklift operation and inspection procedures.

- Consistency: Stick to the weekly inspection schedule religiously.

- Documentation: Maintain thorough records of all inspections, findings, and repairs.

- Corrective Actions: Address any identified issues promptly and effectively.

- Regular Review: Review your checklist periodically and update it as needed to reflect changes in regulations or equipment.

- Calibration and Servicing: Schedule regular professional maintenance and servicing to supplement your weekly inspections.

Conclusion: Prioritize Safety and Compliance

Implementing a robust forklift inspection program is a critical investment in the safety of your workforce, the longevity of your equipment, and the overall efficiency of your operations. By utilizing our free weekly forklift inspection checklist template, you can streamline your inspection process, ensure compliance with regulations, and proactively mitigate potential hazards. Remember, safety is not a one-time event; it’s an ongoing commitment. Download the template today, implement it diligently, and create a safer and more productive work environment.

Frequently Asked Questions (FAQs)

1. How often should I inspect my forklift?

While pre-operational checks should be performed before each shift, weekly inspections are a recommended best practice. This frequency strikes a balance between thoroughness and practicality.

2. What if I find a problem during the inspection?

Immediately remove the forklift from service and report the issue to the appropriate maintenance personnel. Do not operate the forklift until the problem has been corrected.

3. Who should perform the forklift inspections?

Forklift operators should perform the pre-operational checks. Weekly inspections should be conducted by a trained and qualified individual, such as a designated maintenance technician or a certified forklift inspector.

4. Is it necessary to document the inspections?

Yes, comprehensive documentation is essential. It provides a record of your inspection efforts, helps track trends, and demonstrates compliance with regulatory requirements. Your documentation can also be used as proof during an incident investigation.

5. Where can I get my forklift serviced?

Forklifts should be serviced by qualified professionals. Contact your forklift manufacturer or a reputable local forklift service provider for maintenance and repairs.