The HACCP Risk Assessment Matrix Template You Need Right Now: Ensuring Food Safety

Food safety is paramount. From the farm to the fork, every step in the food production process carries potential hazards that could compromise consumer health. That’s where Hazard Analysis and Critical Control Points (HACCP) comes in. HACCP is a systematic, science-based approach to identifying, evaluating, and controlling food safety hazards. A cornerstone of any successful HACCP plan is a thorough risk assessment. And the tool that helps you do that? The HACCP risk assessment matrix.

This article will guide you through understanding the HACCP risk assessment matrix, why it’s essential, and how to use it effectively. We’ll also provide insights to help you create or adapt a template for your specific needs, equipping you to protect your consumers and your business.

What is a HACCP Risk Assessment Matrix?

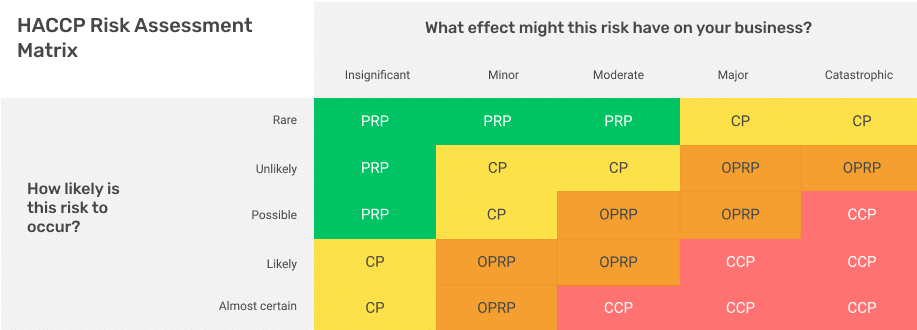

The HACCP risk assessment matrix is a structured tool used to evaluate the likelihood and severity of potential hazards in your food production process. It’s a visual representation that helps you prioritize risks, allocate resources effectively, and ultimately, establish critical control points (CCPs) where hazards must be controlled to ensure food safety.

Think of it as a systematic way to answer the following crucial questions:

- What hazards are present? (e.g., biological, chemical, physical)

- How likely is each hazard to occur? (e.g., low, medium, high)

- What is the potential severity of the hazard? (e.g., minor illness, serious injury, death)

- What are the critical control points (CCPs) to mitigate these hazards?

The Components of a HACCP Risk Assessment Matrix

A typical HACCP risk assessment matrix includes several key components:

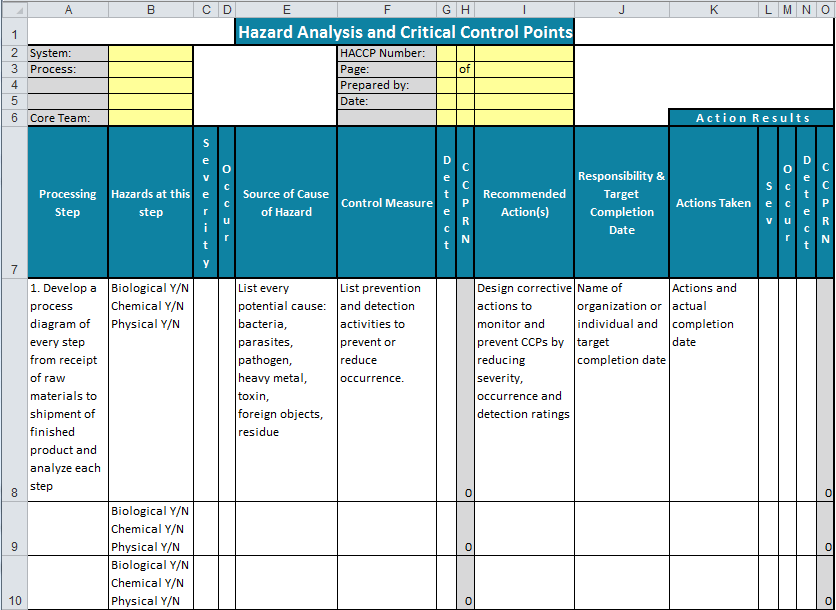

Hazard Identification: This is the first step, identifying all potential hazards associated with each step of your food production process. These hazards can be biological (bacteria, viruses, parasites), chemical (pesticides, toxins, allergens), or physical (glass, metal, plastic).

Likelihood of Occurrence: This assesses how likely a hazard is to occur. This is often rated on a scale (e.g., Low, Medium, High, or numerical scales like 1-3 or 1-5). Factors influencing likelihood include:

- Frequency of the hazard’s presence in raw materials.

- Effectiveness of existing control measures.

- Potential for cross-contamination.

Severity of Impact: This assesses the potential severity of the health impact if the hazard occurs. This is also often rated on a scale (e.g., Minor, Moderate, Major, Catastrophic, or numerical scales). Factors influencing severity include:

- The nature of the hazard.

- The vulnerability of the consumer (e.g., children, elderly, immunocompromised).

- The potential for widespread illness or death.

Risk Rating: This is the result of combining likelihood and severity. The matrix uses a combination (e.g., a 3x3 or 5x5 grid) to determine the overall risk level. For example:

- High Risk: High likelihood AND High Severity

- Medium Risk: Medium likelihood AND Medium Severity OR High likelihood AND Low/Medium severity

- Low Risk: Low likelihood AND Low/Medium severity

Control Measures: This section outlines the specific preventative measures needed to control the identified hazards. These measures should be documented in your HACCP plan.

Critical Control Points (CCPs): Based on the risk assessment, CCPs are identified. These are steps in the process where control is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level.

Monitoring Procedures: This outlines how you will monitor the CCPs to ensure that they are under control.

Corrective Actions: This specifies the actions to be taken if a CCP is not under control.

How to Use a HACCP Risk Assessment Matrix Template Effectively

Here’s a step-by-step guide to utilizing a HACCP risk assessment matrix:

- Assemble Your Team: Gather a team with expertise in food safety, production, and sanitation.

- Describe Your Product and Process: Create a detailed flow diagram of your entire food production process, from receiving raw materials to distribution.

- Identify Potential Hazards: Brainstorm and list all potential biological, chemical, and physical hazards associated with each step of the process.

- Assess Likelihood and Severity: Evaluate the likelihood and severity of each hazard using your chosen rating scales (e.g., Low, Medium, High).

- Determine Risk Rating: Use the matrix to determine the overall risk level for each hazard by combining likelihood and severity.

- Prioritize Hazards: Focus on the high-risk hazards first. These require immediate attention and implementation of control measures.

- Identify Critical Control Points (CCPs): Determine where control is essential to prevent or eliminate food safety hazards.

- Implement Control Measures: Develop and implement control measures, such as standard operating procedures (SOPs), to control the identified hazards at the CCPs.

- Monitor and Verify: Establish monitoring procedures to ensure that the control measures are effective.

- Document and Review: Document all findings and regularly review and update your HACCP plan and risk assessment matrix as necessary.

Where to Find a HACCP Risk Assessment Matrix Template

You can find HACCP risk assessment matrix templates in various formats:

- Online Search: Search for “HACCP risk assessment matrix template” to find numerous examples.

- Food Safety Organizations: Many food safety organizations (e.g., FDA, USDA, GFSI-recognized standards) offer templates or guidance.

- Consultants: Food safety consultants often provide templates and customized solutions.

- Spreadsheet Software: Create your own template using spreadsheet software like Microsoft Excel or Google Sheets.

Pro Tip: Tailor any template to your specific food product and processing methods for maximum effectiveness.

Conclusion: Protect Your Business and Consumers with a Robust HACCP Plan

The HACCP risk assessment matrix is a vital tool for ensuring food safety. By systematically identifying, evaluating, and controlling hazards, you can protect your consumers from foodborne illnesses and safeguard your business from potential damage to your reputation and financial losses. Take the time to understand and implement a robust HACCP plan, and remember to regularly review and update your risk assessment matrix to reflect changes in your operations, new scientific findings, and evolving regulations.

Frequently Asked Questions (FAQs)

What is the difference between a hazard and a risk in HACCP?

- A hazard is anything that can cause harm (e.g., bacteria, glass shards). Risk is the likelihood of that hazard causing harm, considering its severity. The matrix assesses both.

How often should I update my HACCP risk assessment matrix?

- You should review and update your matrix at least annually or whenever there are significant changes to your product, process, equipment, ingredients, or regulations.

Is a HACCP plan legally required?

- Yes, in many countries and for many food businesses. Regulations vary, so check the requirements for your region and the type of food you produce.

Do I need to be a food safety expert to use a HACCP risk assessment matrix?

- While it helps to have some understanding of food safety principles, you don’t need to be a food safety expert. However, it is highly recommended that you have a trained HACCP team and/or consult with a food safety professional to ensure compliance and effectiveness.

Can I use a generic HACCP risk assessment matrix template, or do I need to create my own?

- You can use a generic template as a starting point, but you must adapt it to your specific food product and production process. A generic template alone is unlikely to be sufficient.